[callout style=”silver” font_size=”16px”]

Why Sealcoat Your Asphalt?

Sealcoating can DOUBLE the life of your asphalt by protecting it from its enemies: sun & oxidation, water, gasoline, oil & other car chemicals. Lauer & Sons applies sealcoating products tailored for each particular situation to form a tough protective coating over your parking lot. Sealcoating preserves the investment you have in your asphalt, while at the same time making your property safer, cleaner and more attractive.

Properly designed asphalt surfaces rarely wear out from traffic. Surface deterioration is usually caused by the weathering effects of the sun and rain as well as the softening effects of deicers, gasoline and oil drippings.

|

Oxidation, the graying in color of asphalt pavement, is a sign of fatigue, aging and general surface deterioration. When unprotected pavement becomes oxidized, the asphalt will begin to ravel from the surface making the pavement rough. Once the surface becomes brittle, cracks develop, and the pavement deteriorates. Furthermore, water that accumulates in low spots is a major cause of pavement damage.

|

Instituting a regularly scheduled maintenance program before these damaging elements get a hold on your pavement is important. When you sealcoat asphalt, you double its life by shielding it from a variety of destructive forces. In addition to its practicality, sealcoating also enhances the appearance of your pavement by giving it an attractive, easy-to-clean, slate black color finish.

Silica Sand is added to Neyra Force sealer to provide a heavier wearing surface. The addition of sand also means that the sealer will last longer and will be more skid resistant than sealer which does not contain sand. Typical sand load is 2 to 3 lbs. of silica sand per gallon of the Neyra Force sealer.

|

At Lauer & Sons, we use Neyra Force sealer. We specialize in asphalt sealcoating, repairs, crack sealing, repair of spider-webbing and alligator cracking, sink holes, and line striping. We use our experience, the latest equipment and the finest products available to get the job done right the first time in a timely, cost effective manner.

|

|

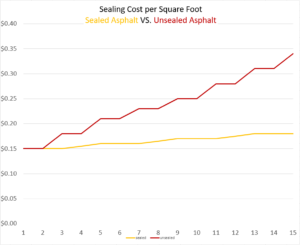

Maintenance costs for unsealed asphalt over a 15 year period

are 50% more than for asphalt that is sealed every 3 years.

|

How Asphalt Deteriorates

|

Air, sunlight and moisture are the major causes of surface deterioration. Unprotected surfaces oxidase and allow the aggregate to be washed away. |

|

Unprotected pavements lose flexibility; aggregate ravels from the surface and the pavement becomes rough. The surface becomes brittle and develops cracks. |

|

Water penetrates the cracks and damage progresses. hydraulic pressure (expansion and contraction) enlarges the cracks. Damage occurs faster under heavy traffic and/or during freeze-thaw cycles. |

|

Cracks allow water to penetrate to the sub-surface and rupture the pavement; causing small cracks to enlarge until the pavement actually separates, creating a pothole. |

"Tests confirm that in just 5 years, the effects of oxidation,

erosion & raveling can reduce the thickness of unprotected

pavement significantly and result in costly repairs or

resurfacing completely." (www.asphaltinstitute.org)

|

[/callout]